Inverter power supplies have become an integral part of modern electronic systems, powering everything from renewable energy installations to consumer electronics. With the demand for smaller, more efficient, and high-performance devices, engineers are constantly seeking innovations that improve energy conversion while reducing size and heat generation. One technology that has emerged as a game-changer in this space is the compact high-frequency core for inverter power supplies. These cores promise to revolutionize inverter design by combining efficiency, reliability, and size reduction in ways that traditional magnetic components cannot match.

Understanding Compact High-Frequency Cores

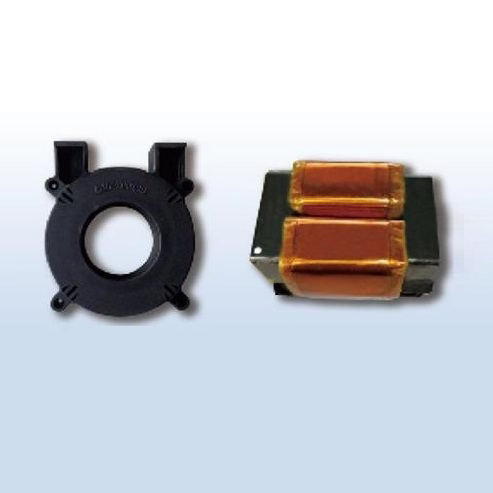

A compact high-frequency core for inverter power supplies is a magnetic component designed to operate at higher switching frequencies than conventional cores. In inverter applications, these cores are essential in transformers, inductors, and chokes, where they store and transfer energy efficiently. By operating at higher frequencies, the magnetic components can be significantly smaller while delivering the same power, which is crucial for space-constrained designs.

Traditional power supply cores, often made of ferrite or laminated steel, face limitations when pushed to higher frequencies. High-frequency operation increases core losses and heat generation, which can compromise performance and reduce reliability. Compact high-frequency cores are engineered using advanced magnetic materials with lower core losses at elevated frequencies, allowing inverters to operate efficiently without the thermal penalties associated with older designs.

Advantages of High-Frequency Operation

Switching to a compact high-frequency core for inverter power supplies offers several advantages that directly impact inverter performance.

Reduced Size and Weight

High-frequency cores allow transformers and inductors to shrink without compromising power output. This is particularly important in portable and compact devices, where every millimeter of space matters. Smaller magnetic components also contribute to lighter inverter systems, enhancing portability and ease of installation.

Improved Efficiency

Core losses, primarily hysteresis and eddy current losses, increase with frequency in traditional materials. Modern high-frequency cores use optimized ferrite compositions and nanocrystalline alloys, minimizing these losses. Lower core losses translate into higher overall efficiency, reducing energy waste and operational costs.

Better Thermal Management

Heat is a critical factor in inverter reliability. Compact high-frequency cores generate less heat compared to conventional cores operating at the same power level. Reduced heat output simplifies thermal management, often eliminating the need for bulky heatsinks and extensive cooling mechanisms. This further enhances the compactness of the inverter design.

Enhanced Reliability and Longevity

By reducing thermal stress and operating efficiently at high frequencies, these cores extend the lifespan of inverter power supplies. Components remain within safe temperature ranges, decreasing the risk of insulation breakdown and other heat-induced failures. This reliability is essential for applications in critical systems such as solar inverters, industrial drives, and medical equipment.

Applications of Compact High-Frequency Cores in Inverter Design

The versatility of compact high-frequency cores for inverter power supplies makes them ideal for a broad range of applications.

Renewable Energy Systems

In solar photovoltaic (PV) inverters and wind turbine converters, size and efficiency are key metrics. High-frequency cores enable more compact inverter designs, allowing installation in confined spaces and reducing material costs. Their high efficiency ensures that more energy from renewable sources is delivered to the grid or storage systems.

Consumer Electronics

Modern electronics demand compact and lightweight power solutions. Laptops, gaming consoles, and high-performance chargers benefit from the reduced size and improved efficiency of high-frequency cores. This results in thinner, lighter devices without sacrificing power delivery.

Electric Vehicles

Electric vehicle (EV) inverters must deliver high power density while maintaining thermal stability. Incorporating compact high-frequency cores allows EV inverters to achieve these goals, reducing the size and weight of the powertrain components while improving overall system efficiency.

Industrial and Medical Equipment

Industrial drives, robotics, and medical devices require highly reliable and efficient power supplies. High-frequency cores ensure these systems can operate continuously under demanding conditions, maintaining performance and safety standards over extended periods.

Design Considerations for High-Frequency Cores

While compact high-frequency cores for inverter power supplies offer significant advantages, their integration requires careful design considerations.

Material Selection

The choice of core material is crucial. Ferrites are commonly used for their low eddy current losses at high frequencies, while nanocrystalline and amorphous alloys offer superior magnetic properties for high-power applications. Designers must balance cost, efficiency, and thermal performance when selecting the optimal material.

Core Geometry

The physical shape of the core affects magnetic flux distribution and thermal characteristics. Toroidal, E-core, and U-core configurations are popular choices, each offering unique benefits in terms of efficiency, manufacturability, and space utilization.

Frequency Limitations

Although high-frequency operation reduces core size, there are practical limits. Excessively high frequencies can introduce electromagnetic interference (EMI) and increased switching losses in semiconductors. Designers must optimize both core and circuit design to achieve the best overall performance.

Thermal Management

Even with high-frequency cores, some heat is inevitably generated. Proper ventilation, heatsinking, and PCB layout considerations ensure that components remain within safe operating temperatures. High-frequency cores simplify thermal management but do not eliminate it entirely.

The Future of Inverter Power Supply Design

The trend toward compact high-frequency cores for inverter power supplies aligns with the broader movement in electronics toward miniaturization, energy efficiency, and high performance. Advances in magnetic materials, core geometry optimization, and integrated design tools are enabling engineers to push the boundaries of inverter design further than ever before.

Emerging technologies such as wide-bandgap semiconductors (SiC and GaN) operate efficiently at higher switching frequencies, creating synergy with high-frequency cores. These cores are no longer just an incremental improvement—they are a foundational element in next-generation inverter systems.

Conclusion

Compact high-frequency cores represent a transformative step in the evolution of inverter power supply design. By enabling smaller, more efficient, and thermally stable power systems, they meet the growing demands of modern electronics, renewable energy, and electric vehicles. The adoption of compact high-frequency cores for inverter power supplies is set to accelerate as designers and manufacturers seek to optimize performance without increasing size or complexity.

Incorporating these cores into inverter design is not just about meeting current standards—it is about future-proofing systems for higher efficiency, better reliability, and more compact form factors. As innovation in materials and power electronics continues, the compact high-frequency core will remain at the forefront of efficient and sustainable inverter power supply solutions.

The era of high-frequency, compact, and efficient inverter design is here, and the compact high-frequency core for inverter power supplies is leading the charge into a more powerful and energy-conscious future.